The Profit Potential of 3D Print Farms

Share

The Profit Potential of 3D Print Farms: Exploring the Lucrative World of Additive Manufacturing

Welcome to the fascinating world of additive manufacturing, where 3D printing is revolutionizing the way we create and produce objects. In this article, we will delve into the profit potential of 3D print farms and explore the lucrative opportunities they offer.

With the rapid advancements in technology, 3D printing has come a long way from being a novelty to becoming an integral part of various industries. From creating prototypes and custom-made products to manufacturing complex parts, the possibilities are virtually endless.

A 3D print farm, also known as a 3D printing factory, is a setup that consists of multiple 3D printers working together to produce large quantities of objects in a shorter span of time. The concept of a print farm allows for streamlining production processes and scaling up operations, making it an intriguing option for entrepreneurs and businesses looking to tap into the ever-growing demand for 3D printed products.

In this article, we will discuss the various factors that contribute to the profit potential of 3D print farms, such as cost efficiency, production speed, and market demand. Whether you are an investor, a business owner, or simply curious about the future of additive manufacturing, this article will provide valuable insights into the fascinating and lucrative world of 3D print farms.

The market potential for 3D print farms is immense, driven by the increasing demand for customized products and efficient manufacturing solutions. As industries seek to reduce costs and improve production timelines, 3D printing technology presents a compelling alternative to traditional manufacturing methods. Entrepreneurs and businesses can capitalize on the versatility of additive manufacturing, offering tailored solutions across various sectors such as healthcare, automotive, aerospace, and consumer goods. This flexibility allows 3D print farms to cater to diverse customer needs, making them a lucrative investment opportunity.

In addition to customization, the rise of on-demand manufacturing is reshaping consumer expectations. Customers no longer want to wait weeks for their products; they desire immediate access to personalized items. 3D print farms can meet this demand by producing goods in real-time, significantly reducing lead times. This capability not only enhances customer satisfaction but also opens doors to new business models, such as subscription services or direct-to-consumer sales. As the shift towards on-demand production continues, print farms stand to gain a competitive edge in a rapidly evolving marketplace.

Moreover, the global 3D printing market is projected to experience significant growth in the coming years. Market research indicates that the industry's value could reach several billion dollars within the next decade. This growth is fueled by advancements in technology, decreasing costs of 3D printers, and the increasing availability of diverse materials. As more businesses recognize the potential of 3D printing to streamline operations and reduce waste, the demand for print farms is likely to surge. Understanding these market dynamics is crucial for anyone considering entering the additive manufacturing space.

Additive manufacturing, commonly known as 3D printing, offers several compelling benefits that set it apart from traditional manufacturing processes. One of the most significant advantages is the ability to produce complex geometries that would be impossible or prohibitively expensive to achieve with conventional techniques. This capability enables designers to innovate freely, creating lightweight and intricate structures that enhance performance and reduce material waste. For industries such as aerospace and automotive, where efficiency and weight reduction are critical, the benefits of additive manufacturing are particularly pronounced.

Another key benefit of 3D printing is its cost-effectiveness for small production runs. Traditional manufacturing often involves high setup costs and long lead times, making it less feasible for low-volume production. In contrast, 3D print farms can produce small batches of customized products without incurring the same overhead costs. This flexibility encourages businesses to experiment with new designs and iterate quickly, fostering a culture of innovation. As a result, companies can respond more swiftly to market trends and customer preferences, gaining a significant advantage in competitive industries.

Additionally, additive manufacturing aligns with sustainability goals by minimizing waste and reducing energy consumption. Unlike subtractive manufacturing, which involves cutting away material from a larger block, 3D printing adds material layer by layer, using only what is necessary. This efficiency not only conserves resources but also enables the use of recycled materials in production. As consumers become increasingly environmentally conscious, businesses that leverage the sustainability benefits of 3D printing can enhance their brand image and attract a loyal customer base.

The growth trajectory of the 3D printing industry has been nothing short of remarkable. Over the past few years, advancements in technology and materials have expanded the capabilities of 3D printing, making it more accessible to businesses of all sizes. From household hobbyists to large corporations, more entities are harnessing the power of additive manufacturing to enhance their operations. This democratization of 3D printing technology has led to a surge in innovation, with new applications emerging across diverse sectors, from healthcare to fashion.

One of the driving forces behind this growth is the increasing investment in research and development. Governments, private investors, and corporations are recognizing the transformative potential of 3D printing and are allocating significant resources to advance the field. This influx of capital is facilitating the development of new materials, enhanced printer capabilities, and improved software solutions, further driving the industry's expansion. As R&D continues to flourish, the possibilities for additive manufacturing will only continue to grow.

Furthermore, the COVID-19 pandemic has accelerated the adoption of 3D printing technology as businesses sought to pivot and adapt to new challenges. Many companies turned to 3D printing to quickly produce essential items such as personal protective equipment (PPE) and medical devices in response to supply chain disruptions. This real-world application showcased the agility and responsiveness of 3D printing, prompting more organizations to explore its potential for rapid prototyping and production. As a result, the pandemic has acted as a catalyst for the industry, solidifying its place as a vital component of modern manufacturing.

Establishing a successful 3D print farm requires careful planning and a strategic approach to operations. The first step involves selecting the right location, which should be accessible, spacious, and equipped with adequate power supply and ventilation. A well-located facility can significantly enhance operational efficiency and facilitate timely deliveries. Additionally, consider the proximity to suppliers and customers, as this can impact logistics and overall costs.

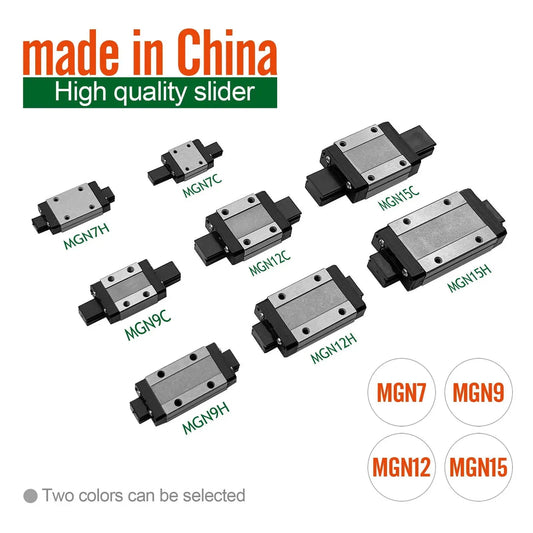

Next, choosing the appropriate technology and equipment is crucial for maximizing production capabilities. Various types of 3D printers are available, each with unique strengths and weaknesses. Factors such as printing speed, material compatibility, and build volume should be carefully evaluated when selecting printers for the farm. Investing in a mix of industrial-grade and more affordable consumer-grade printers can provide flexibility in production, allowing for both high-volume runs and customized orders. Furthermore, incorporating advanced software solutions can streamline design processes and optimize print settings for improved efficiency.

Once the infrastructure is in place, developing a skilled workforce is essential for the success of the print farm. Training employees on the operation and maintenance of 3D printers, as well as design software, can help ensure high-quality outputs and minimize downtime. Additionally, fostering a culture of continuous learning and innovation within the team can drive the farm's growth. By empowering employees to experiment with new techniques and materials, print farms can remain at the forefront of industry advancements and respond effectively to changing market demands.

When starting a 3D print farm, several key considerations must be addressed to ensure long-term success. One of the primary factors is the selection of a business model. Print farms can operate on various models, including contract manufacturing, prototyping services, or direct-to-consumer sales. Understanding the target market and identifying customer needs will help determine the most suitable approach. Conducting thorough market research and competitor analysis can provide valuable insights into the best business model to adopt.

Another critical consideration is the financial aspect of launching a print farm. Initial investments in equipment, materials, and facility setup can be substantial, making it essential to create a detailed business plan that outlines projected costs and revenue streams. Evaluating potential funding options, such as grants, loans, or partnerships, can help secure the necessary capital for startup. Additionally, establishing a pricing strategy that reflects the value of the services offered while remaining competitive is vital for attracting clients and ensuring profitability.

Lastly, regulatory compliance and intellectual property considerations play a significant role in the establishment of a 3D print farm. Familiarizing yourself with local regulations regarding manufacturing, safety standards, and environmental impact is crucial to operating legally and ethically. Moreover, understanding the implications of intellectual property rights in the context of 3D printing is essential for protecting your designs and respecting the rights of others. Implementing robust legal and compliance frameworks can safeguard the business and foster trust with clients and partners.

Security and quality control are paramount in the realm of additive manufacturing, particularly for 3D print farms that handle sensitive projects or proprietary designs. Implementing stringent security measures helps prevent unauthorized access to designs, intellectual property theft, and potential sabotage. Establishing a secure network environment, utilizing encryption protocols, and providing employee training on cybersecurity best practices are essential steps to safeguard valuable information. Moreover, incorporating access controls and monitoring systems can enhance overall security and protect the integrity of the production process.

Quality control is equally critical in ensuring that the final products meet industry standards and customer expectations. Implementing a comprehensive quality management system allows print farms to monitor every stage of the production process, from design to post-processing. Regular inspections, testing, and validation procedures help identify defects early, reducing the risk of costly reprints and dissatisfied customers. Furthermore, investing in advanced quality assurance technologies, such as automated inspection systems or data analytics tools, can enhance the accuracy and efficiency of quality control measures.

Additionally, fostering a culture of quality within the workforce is essential for maintaining high standards. Providing ongoing training and encouraging employees to take ownership of their work can lead to a proactive approach to quality assurance. By instilling a sense of pride and accountability in the team, print farms can ensure that each product reflects their commitment to excellence. Ultimately, a robust focus on security and quality control not only protects the business but also enhances its reputation in the competitive additive manufacturing landscape.

Marketing and promoting a 3D print farm is crucial for attracting clients and establishing a strong brand presence in the industry. One effective strategy is to leverage digital marketing channels, such as social media, search engine optimization (SEO), and content marketing. By creating informative and engaging content that showcases the capabilities and benefits of 3D printing, businesses can position themselves as thought leaders in the field. Sharing case studies, tutorials, and industry insights can help build credibility and foster trust among potential customers.

Networking within the industry is another key component of successful marketing. Attending trade shows, conferences, and local business events can provide valuable opportunities to connect with potential clients and partners. Building relationships with other businesses, suppliers, and industry influencers can lead to referrals and collaborative projects. Additionally, participating in online forums and communities related to 3D printing can enhance visibility and allow print farms to engage with a broader audience.

Finally, offering free trials or pilot projects can be an effective way to showcase the quality and efficiency of a print farm's services. By allowing potential clients to experience the capabilities firsthand, businesses can demonstrate their value and differentiate themselves from competitors. Positive customer testimonials and success stories can further enhance marketing efforts, providing social proof that builds confidence in the print farm's offerings. Ultimately, a well-rounded marketing strategy that combines digital outreach, networking, and hands-on experiences can drive growth and establish a strong foothold in the 3D printing landscape.

Examining case studies of successful 3D print farms provides valuable insights into best practices and strategies for thriving in the additive manufacturing space. One noteworthy example is a print farm that specializes in producing custom medical devices. By leveraging the flexibility of 3D printing, they created a streamlined process for developing prototypes and final products tailored to individual patients. This focus on customization not only improved patient outcomes but also attracted partnerships with healthcare providers, leading to significant growth and recognition within the industry.

Another compelling case study involves a 3D print farm that caters to the aerospace sector. By utilizing advanced materials and cutting-edge printing techniques, the farm was able to produce lightweight, durable components that met stringent industry standards. Their commitment to quality and innovation led to collaborations with major aerospace manufacturers, allowing them to establish a reputation as a trusted supplier of critical components. This case demonstrates how focusing on niche markets and building strong relationships with industry players can drive success in the competitive landscape of additive manufacturing.

Lastly, a print farm that focuses on sustainable practices highlights the potential for environmental responsibility within the industry. By utilizing recycled materials and implementing energy-efficient processes, this farm not only reduced its ecological footprint but also appealed to environmentally conscious consumers. Their marketing efforts emphasized their commitment to sustainability, attracting clients who prioritize eco-friendly solutions. This case study illustrates how aligning business practices with social values can enhance brand loyalty and create a unique selling proposition in the marketplace.

The future of additive manufacturing and 3D print farms is poised for remarkable growth and innovation. As technology continues to advance, the capabilities of 3D printing will expand, enabling the production of even more complex and efficient designs. The integration of artificial intelligence and machine learning into the manufacturing process will further enhance automation and optimization, streamlining operations and reducing production times. This evolution will allow print farms to meet the increasing demand for customized products and rapid prototyping, solidifying their position in the market.

Moreover, the trend towards sustainability will continue to shape the future of 3D printing. As businesses strive to minimize their environmental impact, the adoption of eco-friendly materials and processes will become increasingly important. Print farms that prioritize sustainability will not only contribute to a healthier planet but also resonate with consumers seeking responsible production methods. This shift will create new opportunities for innovation and differentiation in the marketplace, driving growth for those who embrace sustainable practices.

In conclusion, the profit potential of 3D print farms is immense, fueled by market demand, technological advancements, and a growing emphasis on customization and sustainability. Entrepreneurs and businesses that recognize and leverage these trends will be well-positioned to thrive in the lucrative world of additive manufacturing. As the industry continues to evolve, staying informed and adaptable will be key to capitalizing on the opportunities that lie ahead, ensuring a successful future for 3D print farms.